Many teams are facing the same challenge: a shrinking labor pool and increasing pressure to do more with fewer workers. Labor shortages, turnover, and safety concerns are making it harder to maintain efficiency— especially for operations that rely heavily on manual processes.

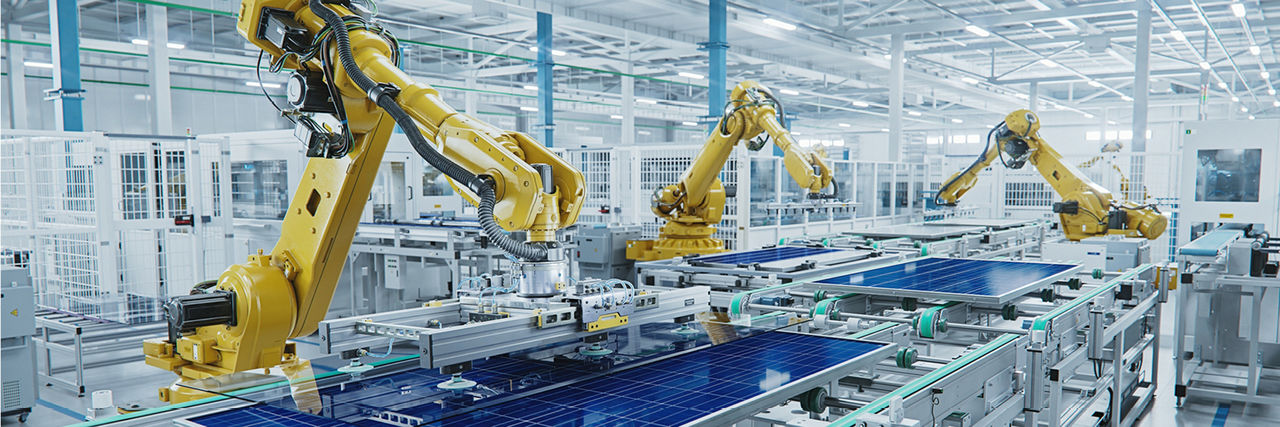

While automation isn’t about replacing workers, it helps ease workforce constraints by taking on repetitive, physically demanding tasks. This allows employees to focus on higher-value responsibilities while reducing the risks associated with labor shortages and workforce fluctuations.